However, most of the experimental literature ignores the effect of finite heat transfer rates (i.e., finite Biot number) on the reactive material containing baskets even though reasonable correlations have been determined theoretically. These parameters can then be used in the F-K theory to predict safe storage conditions for larger sizes, different geometries, and different boundary conditions.

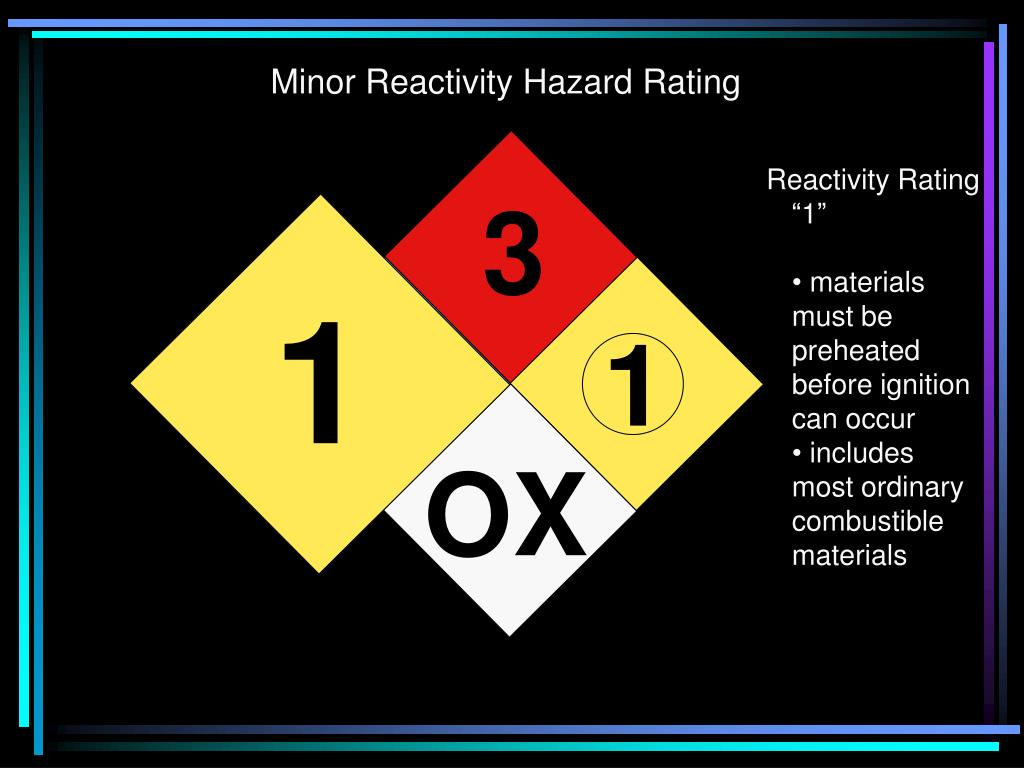

Reactivity hazard series#

After gaining a series of basket size-critical temperature data pairs, a Frank-Kamenetskii graph is used to graphically determine the activation energy and the product of the Arrhenius pre-exponential and heat of reaction. The tests are continued at a fixed basket size by changing the oven temperature for each test in an iterative fashion to bracket the critical ambient temperature for that basket size. The baskets are inserted into a hot isothermal convection oven, and the outcome is monitored for either subcritical or supercritical (i.e., ignition) behavior. Understanding the consequences of runaway reactions or toxic gas evolution.Traditionally, effective kinetic parameters for the Frank-Kamenetskii (F-K) thermal explosion model have been obtained through the use of ignition tests on baskets of reactive solid materials. Effect of variables such as charging rates, catalyst addition, and possible contaminants. Thermal stability of reactants, reaction mixtures, byproducts, waste streams, and Maximum operating temperature to avoid decomposition. Rate and quantity of heat or gas generated. In revising this element, evaluate the need to consider relevant factors, such as:

Information developed from computerized tools (e.g., ASTM's CHETAH, NOAA's The Chemical Reactivity Worksheet).

Literature surveys (e.g., Bretherick's Handbook of Reactive Chemical Hazards, Sax's Dangerous Properties of Industrial Materials).

Additionally, broaden coverage of hazards from self-reactive chemicals.

Reactivity hazard drivers#

Drivers of Critical Chemical Safety Change.CSB Budget Requests and Strategic Plans.

0 kommentar(er)

0 kommentar(er)